PROJECTS

Key Facts & Figures

About the Project

With our ISO 22001 Food Safety Management System accreditation, we ensure that we are running our day-to-day activities in line with best industry standards.

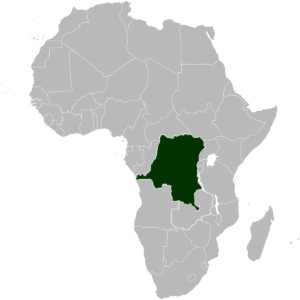

Kibali Gold Mine (KGM) is located in the North East of the Democratic Republic of Congo (DRC), approximately 560km northeast of the capital of the Oriental Province Kisangani, 180km west of the Ugandan border town Arua and 1,800km from the Kenyan port of Mombasa.

The Kibali Gold Mine site comprises of 3,000 employees, the average meals served by GCS per day are approx. 1,750 and GCS provides cleaning and laundry services for 960 rooms. KGM is the third biggest investment in the DRC and is currently employing close to 3,000 people and during the height of construction it employed 12,500 people. KGM is a major catalyst in transforming the province economically and politically, and has a policy of growing to involve the local community as much as possible, increasing the skill and workforce across the region.

A look into our services offered

Catering

Provision of nutritional and balanced meals for all day and night shift staff on duty delivered to the plant site in containership. High control ticket/scanning system for clients served in the canteen areas Management of all functions on site as well as catering at community events.

Recreational bars, restaurant , take away and shops

Over 502 stock items available thus increasing the value added to shop items and increasing the average basket size per shopper. A new satellite shop on the plant site mine area has been set-up with fast moving items, increasing convenience for staff, management and night shift individuals. Increased size of the restaurant menu, bar items and drinks menu providing more options for staff, management and guests. A high focus on minimal food waste.

Housekeeping and laundry

All rooms are serviced and managed on a daily basis. Laundry is collected from rooms, taken to the laundry room, marked with tags and documented in a manual system for tracking purposes. Laundry is done every second day, washed, dried, pressed and packed in the respective room laundry bags. All bedding is washed on a weekly basis with replacements fitted on the day of the wash cycle for bedding items. All lost and found items are returned to the managers office. All towels are removed on the same day for washing and returned on an alternate day.

Guest management

On arrival on site, guests, clients or employees are checked in at the reception and provided with a room/tent key and number and escorted to their room and shown all the facilities available. New guests are issued with a set of rules, emergency contacts on site, a map of the area, hospital and dining room services are provided to all guests. Government guests are also managed when on site. Guests are checked in on both a computerized and manual system to show occupancy of the camp at all times.

Guest house

Recreational food is organized on request at the KGM Entebbe Guesthouse.

Go Back

Key Facts & Figures

About the Project

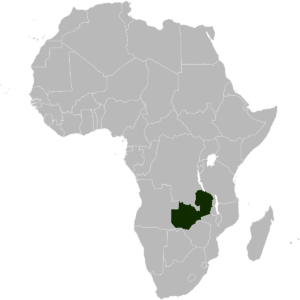

Lumwana Mining Company (LMC) is a conventional open pit (truck and shovel) operation. It’s located about 100 kilometers west of Solwezi in Zambia’s Copperbelt — one of the most prospective copper regions in the world. LMC comprises of about 5,000 employees and during construction the company employed about 15,000 direct employees. GCS has been subcontracted to provide catering and housekeeping services for the employees. GCS provides an average of 4,300 meals per day and services about 2,200 beds per day. The average square meters cleaned by GCS per day is 23,000 sq m.

LMC is a major catalyst in transforming the province economically and has a policy of growing to involve the local community as much as possible, increasing the skill and workforce in the region. The company has pledged to empower more people in the province through its robust corporate social responsibility programme and has so far invested USD 13 million over the last 10 years.

A look into our services offered

Catering

Provision of nutritional and balanced meals for all day and night shift staff on duty delivered to the plant site in containership. High control ticket/scanning system for clients served in the canteen areas. Management of all functions on site as well as catering at community events.

Recreational bars, restaurant , take away and shops

Over 650 stock items available thus increasing the value added to shop items and increasing the average basket size per shopper. A new satellite shop on the plant site mine area has been set-up with fast moving items, increasing convenience for staff, management and night shift individuals. Increased size of the restaurant menu, bar items and drinks menu providing more options for staff, management and guests. A high focus on minimal food waste.

Housekeeping and laundry

All rooms are serviced and managed on a daily basis. Laundry is collected from rooms, taken to the laundry room, marked with tags and documented in a manual system for tracking purposes. Laundry is done every second day. Washed, dried, pressed and packed in the respective room laundry bags. All bedding is washed on a weekly basis with replacements fitted on the day of the wash cycle for bedding items. All lost and found items are returned to the manager’s office. All towels are removed on the same day for washing and returned on an alternate day.

Guest management

On arrival on site, guests, clients, or employees are checked in at the reception and provided with a room/tent key and number and escorted to their room and shown all the facilities available. New guests are issued with a set of rules, emergency contacts on site, a map of the area, hospital and dining room services are provided to all guests. Government guests are also managed when on site. Guests are checked in on both a computerized and manual system to always show occupancy of the camp.

Go Back

Key Facts & Figures

About the Project

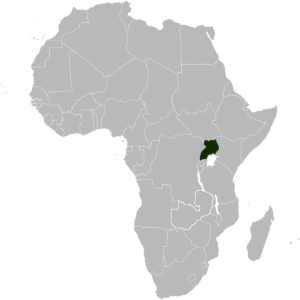

Our Guesthouse is located five minutes away from Entebbe Airport (Uganda), providing catering and housing in a comfortable area for our clients in transit.

We offer a bar service, an à la carte menu and can organize functions.

- Total GCS staff : 7

- 40-50 meals a la carte

A look into our services offered

Catering

Provision of nutritional and balanced meals for all day and night shift staff on duty delivered to the plant site in containership High control ticket/scanning system for clients served in the canteen areas Management of all functions on site as well as catering at community events

Go Back